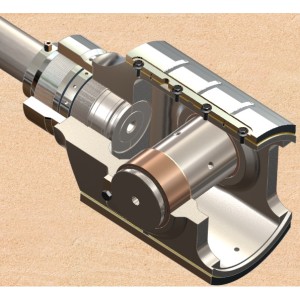

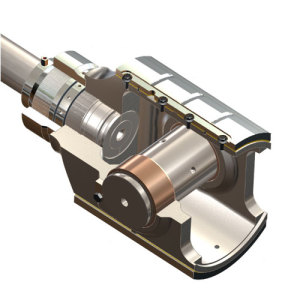

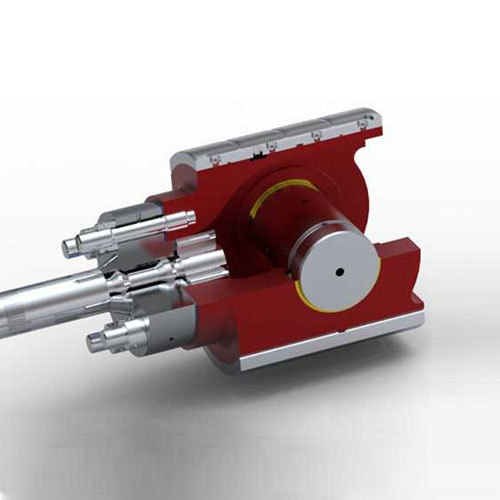

Crosshead body

| Categories | Crosshead assembly |

|---|---|

| Update Time | Apr 20,2024 |

Detail Information

Details

The crosshead is a part that connects the piston to the connecting rod and has a guiding effect. A large number of closed crossheads with small connecting rods placed in the crosshead body are used in the compressor, and a few compressors use an open crosshead that matches the forked connecting rod.

A compressor with a crosshead in the moving mechanism. The working surface of the cylinder is not subjected to the side pressure transmitted from the connecting rod, the friction and wear between the cylinder and the piston are small, the cylinder volume is fully utilized, and the lubricating oil is easy to control; the packing sealing can be provided, and the gas leakage is small, but the compressor is added. The components such as the + head, the piston rod and the packing make the structure of the machine complicated, and the height and weight are also increased accordingly. This type of structure can only be used for compressing flammable, explosive, and toxic gases.

The connection type of the crosshead and the piston rod is divided into a screw connection, a hydraulic nut connection, a coupling connection, a flange connection, and the like. The threaded connection structure is simple, and it is easy to adjust the dead space in the cylinder. However, when the adjustment is required, the piston needs to be rotated, and when the thread is cut on the crosshead body, it is easily worn after being disassembled a plurality of times, and it is difficult to ensure the accuracy requirement. Therefore, this structure is often used on medium and small compressors.

The thread is not cut on the crosshead body, but the bolt is fastened with the flange clamp connection. However, when the disassembly and assembly, the bolt installation space is limited, the special tool is inconvenient and difficult to apply force, and the tightening torque is difficult to reach the force of each bolt. Consistently, the clamping flange and the crosshead end face cannot guarantee the uniformity of the four sides. Nowadays, large and medium-sized compressors mostly adopt hydraulic nut connection structure, which consists of hydraulic pump, high-pressure hose, pressure gauge and tensile body. The tensioner is installed at the axial position of the tail end of the piston rod and the end surface of the crosshead, and is axially stretched by a pure pulling force, so that the elastic deformation zone is elongated in the middle of the crosshead end of the piston rod, and the diameter is slightly deformed to achieve a strict rated pressure. The amount of stretching, after the outer nut lock is tightened, the oil pressure is removed to achieve the connection fastening. The utility model has the advantages of simple and convenient operation, small volume, light weight, compact structure, high strength, stable and safe use, high efficiency and quickness.

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription